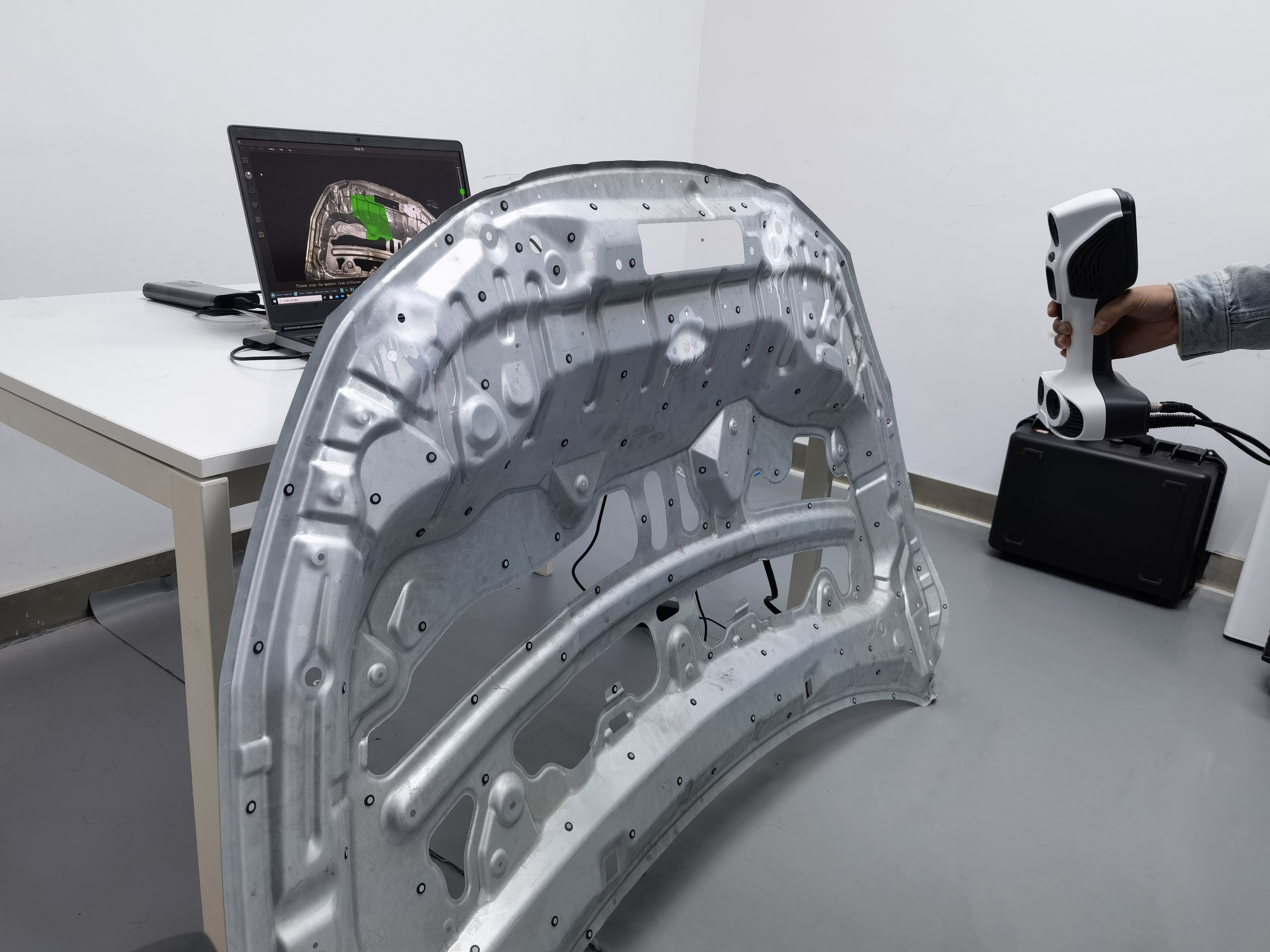

3D Scanning

3D scanning is the process of capturing and collecting data from the surface of an object to create a three-dimensional digital model

Reverse Engineering

Reverse engineering is the process of deconstructing and analyzing an existing product or system to understand its design, functionality, and components

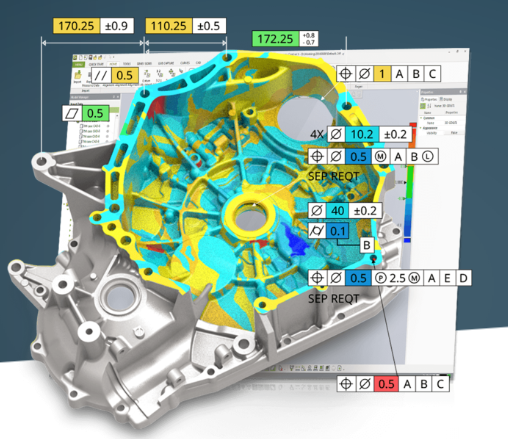

Digital Inspection

3D inspection is the use of 3D scanning technology to compare a physical object to its corresponding 3D digital model in order to identify any deviations or defects

Happy Clients

Projects

Years of experience

CAD Training

Pheonix 3D Metrology and Design Solutions

At PHEONIX 3DM, we have years of experience and expertise in delivering cost-effective and premium quality solution for all your drafting, technical and digital needs. Our mission is to offer complete value to our customers by providing them with engineering and related services using the very latest technology and software.

- Develop and build prototypes in digital format, and thereby, decrease the cost of product development

- Acquire an in- depth insight about the products of your competitors with 3D CAD modeling

- Optimize the quality of the product by obtaining insights through 3D scan to CAD conversion

- To match shop-floor changes, we update CAD models

- Redesign a part of your product without manufacturing flaws through virtual inspection and simulation